Curtis and Yale

Curtis and Yale

In 1881, a new plant was built in Wausau by the Curtis Brothers & Company of Clinton, Iowa. After 15 years of operating their Iowa business, the Curtis Brothers sent the youngest brother, Cornelius S. Curtis to oversee the new branch in Wisconsin.

“A notable addition to the lumber interest of Wausau is being made in the erection of a mammoth sash, door and blind factory by the Curtis Brothers, of Clinton, Iowa. That enterprising firm will manufacture direct from the log, taking their supply from the Wisconsin river, on the west bank of which, high and dry, above all reach of flood, they are building their steam factory and mill. Their enterprise will involve a large outlay and is regarded as full of most assuring promise of profit.”

-Editorial Correspondence in the Davenport Weekly Gazette (Davenport, Iowa), dated August 24, 1881 (published in 31 August, 1881)

The Curtis plant built on the west bank of the Wisconsin River was designed to manufacture products from the lumber harvested from the region, which set it apart from the other mills established to cut down the logs. They turned the lumber into flooring, wood siding, window sashes, door frames, and Venetian blinds.

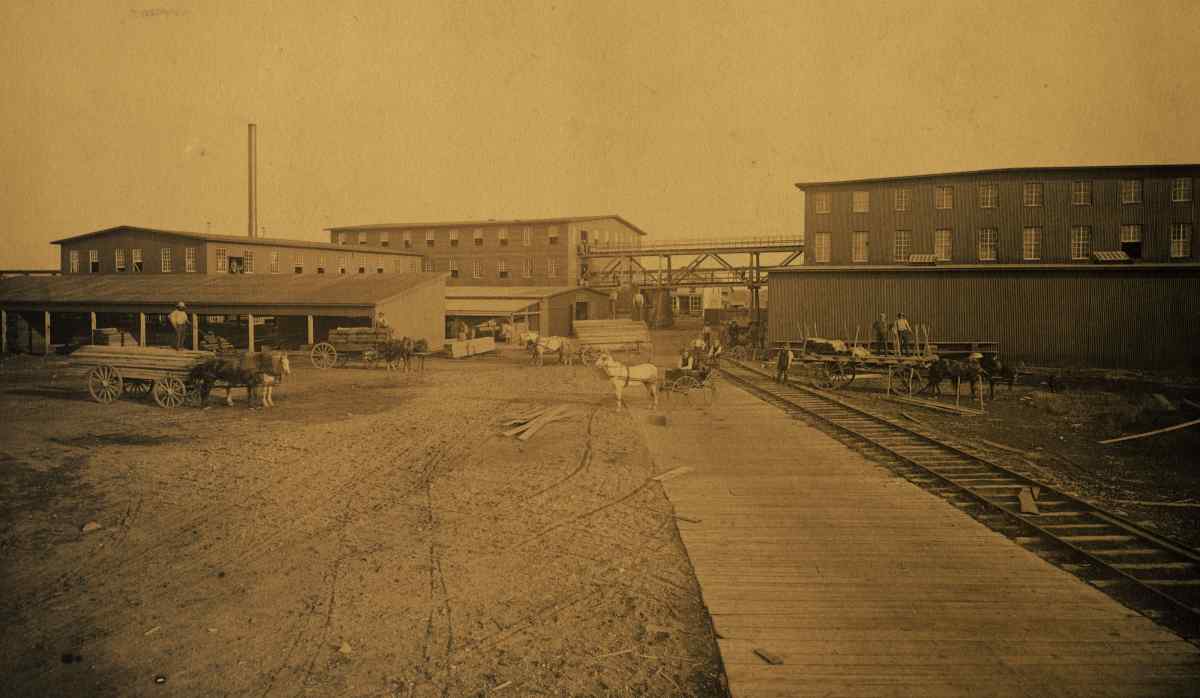

^ The Curtis and Yale Plant No 1., looking south towards Scott Street and the Wisconsin River.

Expansion

Over the years, the company has changed names to reflect the addition of new partners who joined the Curtis Brothers, often to expand the reach of the company. The first and most important of these new partners was Stephen M. Yale, who had left his home in Minnesota to work for the Curtis Brothers; first in Iowa between 1880 and 1882, and then in Wausau for a decade. In 1893, Yale was elevated to partner in the company and sent back to Minneapolis in 1893, where he expanded the company by establishing first a supply depot (1893) and then a warehouse and salesroom (1898).

Other offices were opened across the country by the 1910s. In his 1913 overview of the company, Louis Marchetti noted that Curtis & Yale had expanded to include jobbing houses in Minneapolis and Detroit, sales offices in Pittsburgh and Washington, D.C., and a purchasing office in Spokane, Washington. Some divisions took on other investors, such as the Minneapolis division becoming Curtis-Yale-Holland in 1919 with the addition of L.B. Holland as vice president of that facility. Wausau's division remained named Curtis and Yale until it was simplified under the name Curtis Companies in 1937.

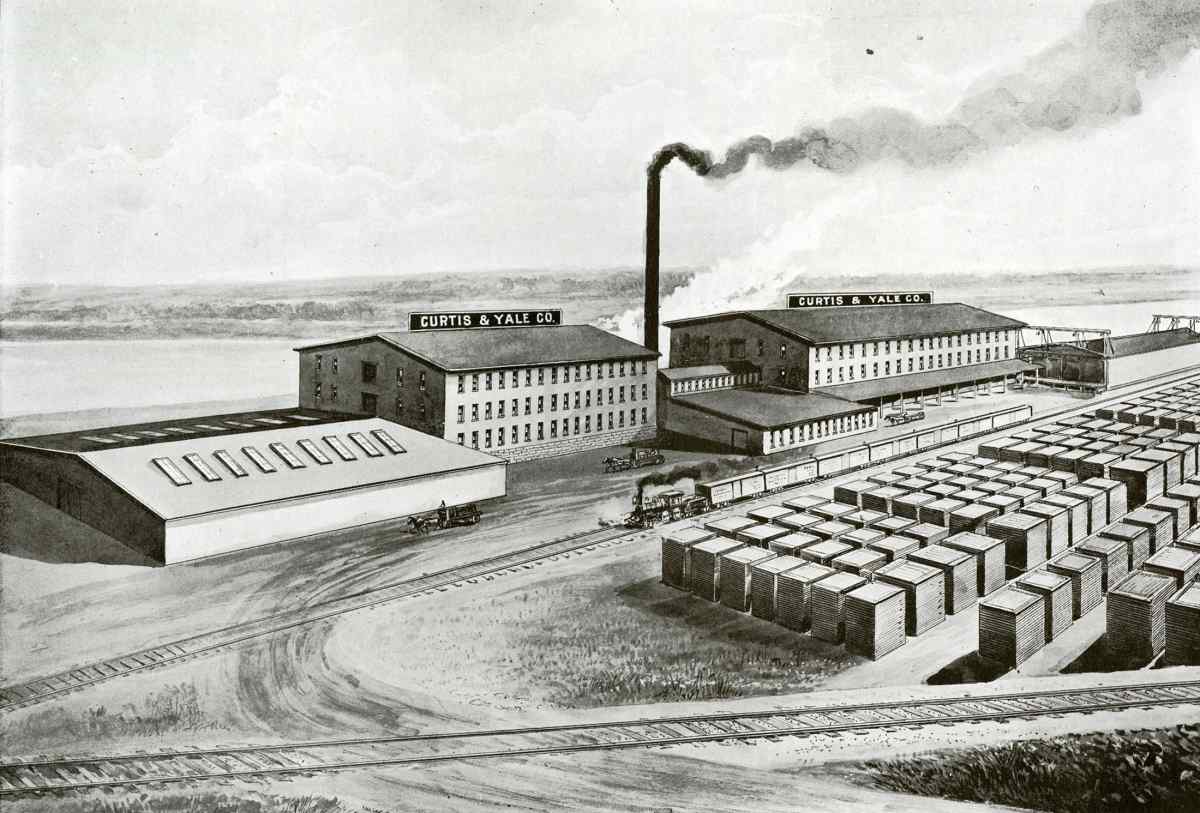

^ Curtis Plant Number 2

The Wausau branch also underwent expansion when in 1899, it purchased the former Wausau Furniture Co. plant several block to the south, and added several new buildings. The Curtis Plant Number 2 opearted until the late 1920s, when it was sold to the 3M plant, and Curtis consolidated its operations at factory no 1.

Curtis and its Employees

By the turn of the century, Curtis & Yale's successful business, combined with the labor-intensive nature of the manufacturing led the company to become one of the leading employers in Marathon County. The nature of the door and sash business made it difficult to provide steady work year round, and typically the workers were brought in for work seasonally when orders were plentiful.

But by the twentieth century, working for Curtis & Yale had other benefits, as the company provided a number of progressive benefits for their employees. In the 1910s, these included giving old age pensions (1913), signed on to agreement with other manufacturing companies to limit the hours of work for minors to allow them to attend 3 hours of school each weekday (1916), gave employees insurance policies (1918), and established a factory library (1919).

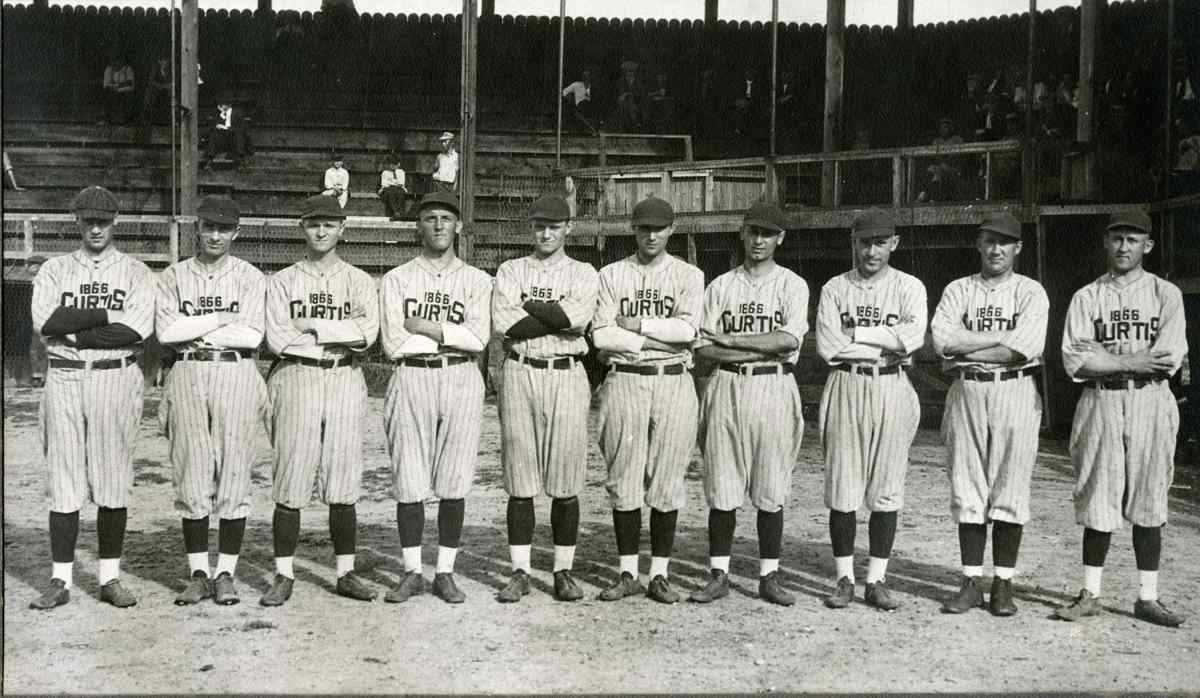

^ Baseball was often a part of working at Curtis. Whether it was occasional games between the employees of plants one and two, or as members of the Industrial League. They won the softball league in 1937, after clinching a game against 3M's Miners, 4 to 2.

Although some of the Curtis employees in Wausau did unionize under the International Woodworkers Association (Local 373), management of Curtis was on the record as being in favor of "The Wausau Policy" which stressed the importance of an "open shop" (in practice it was also explicitly anti-union). Still the steady work and wages combined with a benevolent attitude toward its employees mostly helped keep Curtis & Yale from clashing with labor.

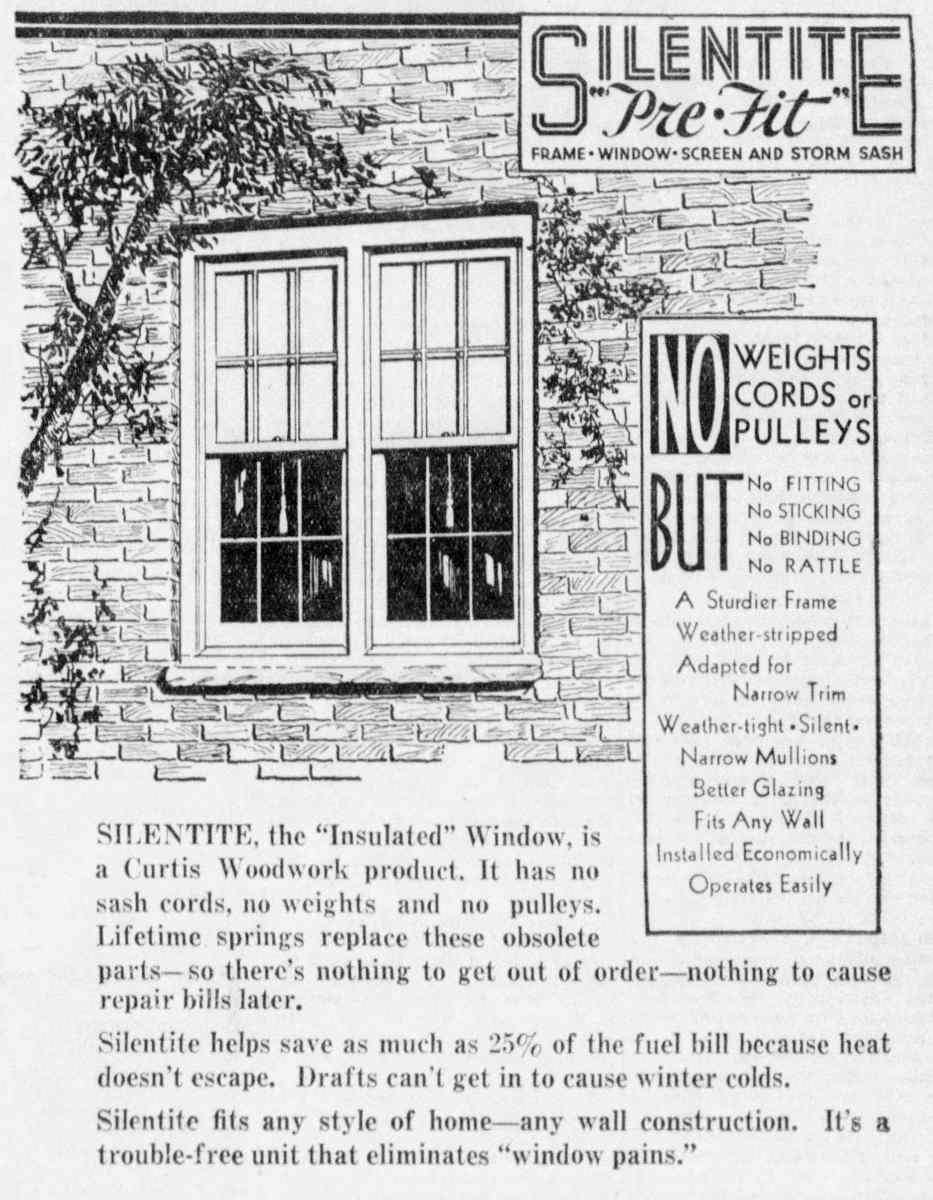

Silentite Windows

In 1932, Curtis introduced a model of “pre-fit window units” under the nationally-known brand Silentite. In many ways the Silentite window was revolutionary, and foreshadowed the rapid changes in window technology of the next fifty years to come.

The Silentite windows were developed to take advantage in new forms of weatherstripping, which led to windows that would be better insulated against the elements.

“Silentite operates without weights or cords; it is weatherstripped by the best method known to the industry and is particularly effective in shutting out dirt, dust, drafts, and in eliminating other common faults of the ordinary double hung window.

“The adaptability of the window was proved in a series of highly scientific tests conducted in wind tunnels where it was possible to control the climate and change it in a moment from a gentle summer breeze to a howling winter blizzard. It was found that where the ordinary window will let in cold, this new widow was many times as impervious to air-leakage as the ordinary window. That means that where the ordinary window will let in cold, this new window is fitted so that it keeps the cold air out.”

“Curtis Company Celebrates 58th Birthday in ‘39” WDH Centennial Edition (13 March, 1939).

Furter developments led to new models of the standardized windows. The "new Silentite Window Unit" as marketed in the mid 1940s, was not only weatherproofed, but consisted of everything a home owner or contractor would need to install them. Up until this point, you might purchase a window frame or sash from Curtis, but need to find hardware for the window from another place, and then have specialists install the glass and molding to finish the window. But as the Curtis product catalog explained, Silentite windows came as "a complete opening, consisting of a frame, window, sash lock, interior trim, screen and storm sash... Each part is so designed that as a unit, all harmonize and fit perfectly as they come from the factory ... [in] dustproof cartons."

This development also helped stabilize what had previously been irregular work for many of the employees. Rather than react to the orders for windows for projects, Curtis & Yale could produce packaged, standardized windows for distribution.

Advertising Curtis Products

^ Ruby Haller modeling for a Curtis & Yale advertisement. Although the designer woodwork produced by Curtis was developed at the headquarters in Iowa, the Wausau division did produce its own marketing.

Since 1920, Curtis & Yale had hired notable designers to come in and redesign their lines of woodwork. By having respected architects redesign their products, Curtis mass produced products that felt authentic and stylish.

For example in 1938, notable New York architect, Dwight James Baum, was contracted to redesign some of the Curtis products. Baum was also a longtime adviser to Good Housekeeping Magazine, and he used Curtis cabinets as part of the house Good Housekeeping built for the World’s Fair.

Curtis Closes the Wausau Division

In 1961, Curtis Companies announced a project to reorganize their plants in the hopes that a more streamlined company might help bring some needed financial stability. The combination of rising costs to produce modern windows and the changing of architectural styles away from the ornate woodwork for which Curtis was known, led to declining sales for all of the Curtis divisions.

To the surprise of everyone in Wausau, they announced on April 30th, 1962 that the Wausau plant would be closing its doors. Before the announcement, the Wausau division employed 265 hourly wage employees and 20 office workers, with a combined payroll of over one million dollars. It was a surprise to everyone in Wisconsin, as the Wausau Division seemed to be doing well. Some employees learned that morning after being contacted by telephone. Most only heard about the closing after it was announced on a radio broadcast that told workers not to bother coming into work that day. The rest of the Curtis Companies faciltiies were in trouble too, and in 1966 the home plant in Clinton, Iowa closed its doors.

The going question at the time, was what would happen to the land where the Curtis factory had sat for the better part of a century. Though the equipment from the Wausau operations was either redistributed to the other Curtis plants or sold to other companies, it was harder to find a new buyer for the facilites.

In the early 1960s, Kolbe & Kolbe (who were looking to start producing their own windows rather than distributing other companies) were briefly in talks to purchase the Curtis facility off Bridge Street. But in the end they decided the facilities there would not be big enough to fit their goals of producing windows, and it would be several years until they built their facilities on Wausau's South West side.

^ Demolition of the Curtis Plant, to make way for a new Riverside Plaza / West River Shopping Center.

But, by that point the other wood window manufacturers in the region undoubtedly benefited the availability of skilled woodworkers left in the wake of Curtis' closure, and therefore the Curtis experience continued the tradition of window manufacturing in the region even after the facility closed.